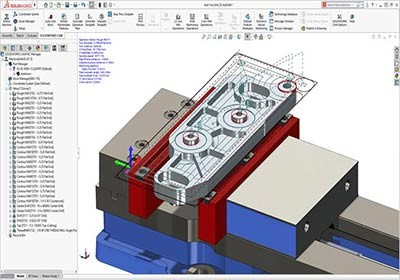

The CAM data is included in the same file like the 3D Model, no additional files for tehnologies and in this way we eliminate a lot of errors by using the wrong strategies to a 3D Model.

Manufacturing tasks that had to wait until a design was complete can now be performed concurrently with the design process leading to better communication and reduced errors. SOLIDWORKS CAM is an add-on to all versions of SOLIDWORKS CAD that lets you prepare your designs for manufacturability earlier in the development cycle. Knowledge Based Machining is the foundation for streamlining the programming process, learning as you program which frees up your time to focus on the critical areas of the components.

It leverages the rich content in the 3D CAD model to speed up product development and reduce error prone, time consuming, repetitive manual steps in the current development process, like programming CNC machines. SOLIDWORKS® CAM is a fully integrated, Knowledge Based Machining (KBM) technology that allows you to integrate design and manufacturing processes under one system to evaluate designs earlier in the process to avoid unexpected costs and delays in finishing products on time.

0 kommentar(er)

0 kommentar(er)